Flatlands at the atomic scale

- Neha Kondekar

- Jun 2, 2020

- 4 min read

Updated: Jun 8, 2020

What’s common between the Sahara desert and the electronic chips that power your phone? Sand, or to speak in scientific terms, Silica. Both sand and the electronic chips are made of Silica which is oxidized Silicon (Si). The only difference between them - the chips are made after processing the sand grains many times over to obtain pure Si. And your phone has one chip made with billions of transistors, all made with Silicon. The transistors are the operating brain of your computers. They make your phones, bulbs, and even houses, ‘smart’. And Silicon is the wonder material that the transistors are made of. The material which has revolutionized computing is literally a processed version of sand. A grain of sand has 10,000,000,000,000,000,000 atoms of Silicon - that’s a billion times billion atoms.

To give you an idea how tiny these transistors that power our phones have become, imagine your hair to be as thick as a football stadium. Then, the length of a modern transistor would be smaller than a house fly (~1 mm). If you wonder, how have we been able to produce this ‘Honey, I shrunk the kids’ remake, the answer is - incredible achievements in fabrication at the nanoscale (A nanometer is a billionth of a meter or 10^-9 m) and engineering. Only very sophisticated factories can manufacture these chips, under very controlled environments. Any dust, from us shedding our skin or just from the ambient room, can alter the electronic properties of these nanoscale transistors, so the humans need to be covered in something very similar to a hazmat suit inside a ‘cleanroom’. And it doesn’t end there. There are literally hundreds of manufacturing steps involved in making these devices. Think of it as your favorite cake recipe. Now add to it, 10 different ovens, several different cake flours, toppings and flavors, all while using very precise weights of the ingredients. In fact, precision down to the scale of a few atoms in thickness. Similar to how you weigh your ingredients using a kitchen scale, the manufacturers use tiny scales to monitor the growth of these materials. The most advanced cameras and ovens are used to precisely control the temperature and environment that these transistors grow in.

Today, the smallest transistor is 100 million times smaller than a grain of sand. It’s because of these tiny transistors that we have been able to shrink the computer size from that of a room to one which fits in our pocket. To improve their speed and power from here, they need to be shrunk further so that more of them can be added to a device without making it too big or bulky. But you know how when you are trying to lose weight, it only gets harder after you have lost the first 5 pounds. There’s a limit to how much you can shrink anything, even at the nanoscale. And for these transistors, we are at the limit. We can’t shrink the silicon transistors anymore.

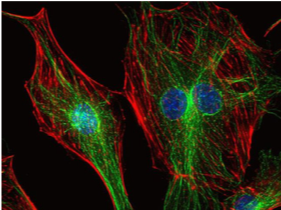

But with the demand for more powerful phones and devices only increasing, scientists have started thinking outside of the Silicon box. There’s a whole class of materials which can be made to be two dimensional - just three atoms across. That’s 10 times smaller than the smallest Si transistor today. One such material that scientists are very interested in right now is MoS2 or Molybdenum Disulfide. Transistors made with MoS2 work very similar to those made with Si in terms of the physics, carrying current and turning on and off like a lightbulb, but 100 billion times per second to ‘smarten’ your devices. But because they are smaller, they need less power, generate less heat and can be more powerful gadgets. Also, their electron transport properties are significantly different from that of Si. Think of it as driving through a flat farmland versus through a mountain. There’s no driving uphill for an electron on an MoS2 flatland.

So if MoS2 is a wonder material, why don’t we have it in our phones already? Well, that’s a question that keeps me up at night too. As a Ph.D. student trying to answer that question, I study the nature of interactions between these atomic flatlands with the rest of the mountainous world. For instance, tiny amounts of gold is used to make electrical contacts to the MoS2 part of a chip, which then completes the electron circuit for current to flow. Yes, the same Gold that your jewelry is made of. But MoS2 doesn’t like to have mountains of Gold on its flatlands or in other words, the electrons feel this revulsion as a resistance to their flow. Moreover, the flatlands roughen up due to surface oxidation - same process that rots an Apple (not the company) once it is cut. Finally, the manufacturing process involves heating the MoS2-Gold contacts but Sulfur (S) being a very reactive element bonds with Gold to form black gold sulfide which doesn’t conduct electricity well. All these processes concerning the surface of the flatlands are a problem. They slow down the transistors, slower than the Si ones. And if they are slow, no one would want to put them in their phones. So there’s only one solution - understand and engineer the surface of MoS2 so that it can interact with Au and the rest of the environment better. That’s what I am trying to do in my Ph.D. research. Using sophisticated instruments, I have been able to understand real-time dynamics of these chemical reactions across the flatlands and am closer to engineering a different configuration of a transistor with significantly improved electronic properties. But does that mean MoS2 is going to change the way we live, only time will tell.

While research is slow and takes a lot of patience, it is the most powerful weapon to produce technology that can directly improve our lives. From electricity to the light bulb, the world wide web to the DNA’s double helix, a lot of what we take for granted today is because brilliant scientists shared their findings with the world and we are all taking a step in that direction with Comm’on Tech!

Comments